Breaking Down Important Requirements for Successful Dental Soldering

In the dental lab, soldering is a necessary part of the job. Due to its wide range of applications, soldering has retained its relevance in dental technology despite the advancement of modern welding and bonding procedures. The daily number of soldering procedures in the dental lab still far outnumbers other joining methods.

In this article, you may find some insightful information on how to achieve a successful soldering result.

What is Soldering?

Soldering is the most prevalent process for joining metal components, and the principles behind it will not alter in the future. Solder is a molten filler metal that is used to connect pieces of metal. The filler metal's processing temperature is lower than the solidus point of the alloys to be bonded. During soldering, the solder moistens but does not melt these alloys.

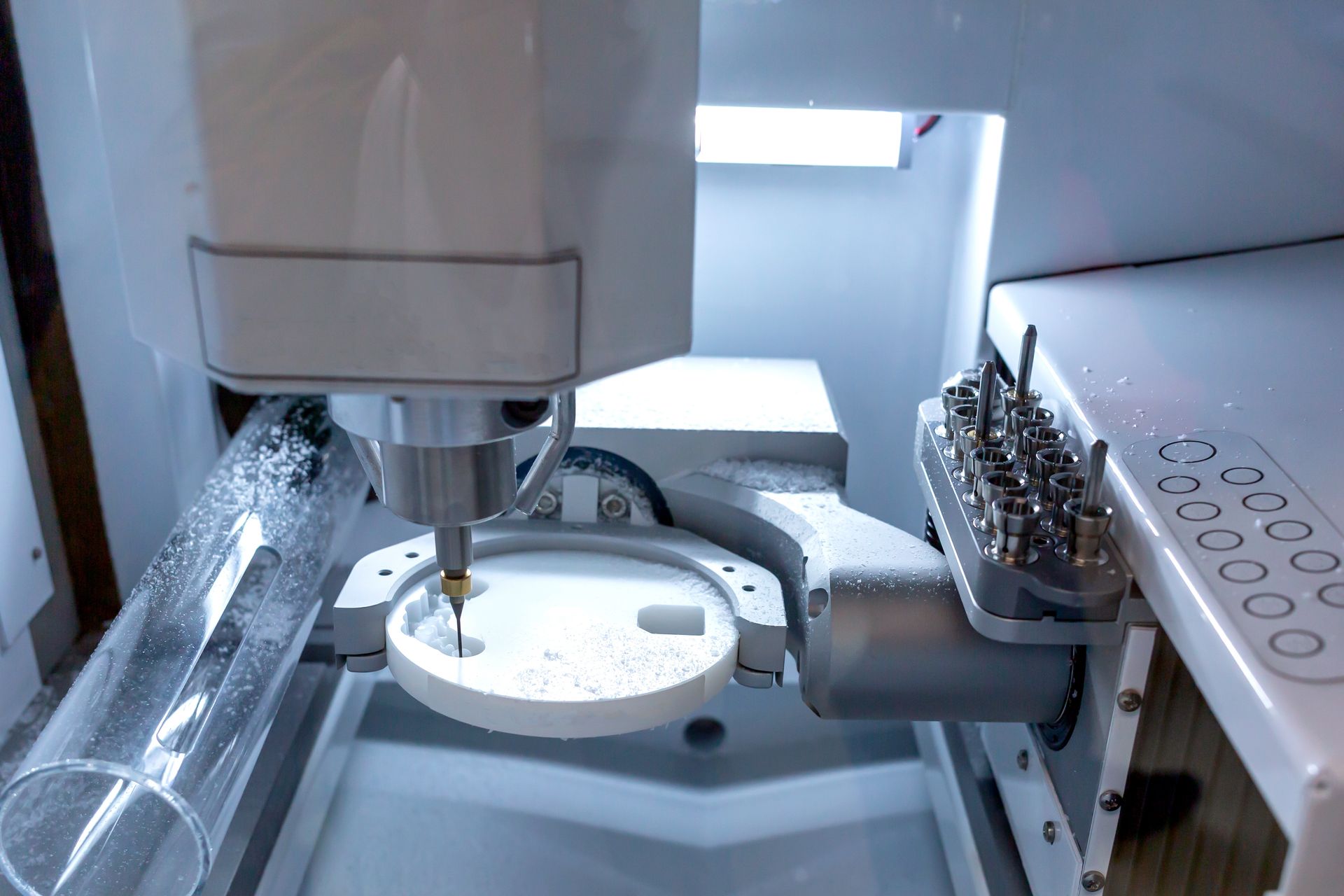

In the manufacturing of dental equipment, soldering is often employed. Large partial dentures are usually made in pieces and soldered together after being meticulously fitted to a master cast.

What are the Six Requirements for Dental Soldering?

A thorough grasp of the materials used in the soldering process and how to appropriately apply them are essential components of a cautious approach to soldering.

1. Metal Compatibility

The solder used in the soldering process should have a processing temperature appropriate for the alloys being soldered. Dental solder must be resistant to the oral environment and have a comparable composition to the alloys that are being fused. This means that for a successful solder bond, metallurgical compatibility and equal coefficients of thermal expansion of solders and alloys are required.

2. Clean Metallic Surfaces

The contact surfaces should be free of grease and oxide, which can be achieved through grinding or sandblasting.

3. Preheated Framework Components

To achieve enough flow and optimal wetting of the alloy, the framework components to be connected should be suitably warmed. The temperature at the soldering site should be higher than the solder's processing temperature but not higher than the alloy's solidus temperature.

4. Wettability

If the solder has excellent wetting qualities, it will flow evenly across the alloy, wet both surfaces, and fill the soldering gap. It produces droplets if the solder has a low wettability. The solder does not flow, and diffusion does not occur in this scenario; in other words, the metal compounds in the alloy and the solder do not combine.

5. Oxide-Dissolving Flux

Flux dissolves the oxygen compounds on the alloy's surface. The flux absorbs the oxides during the dissolving process and prevents any further oxidation.

6. Parallel Soldering Gap Walls

When the pressure is removed, the solder is forced into the soldering gap only if the walls of the framework components are parallel to one another. The walls should be lined at a width of around 0.05 mm to no more than 0.2 mm, with equal space between them.

Conclusion

Dental solder is suitable for both orthodontic and restorative situations. To join other metal restoration components or to restore cast metal frameworks, these tiny metal wires are heated and melted. When buying dental solder, check the high-end melting range to make sure it's lower than the low-end melting range of the metal you're soldering to.

If you are looking for a reliable dental lab, Vitality Technologies is a full-service dental laboratory serving dental offices nationwide. We specialize in dental implants, fixed prosthetics, high-end removable dentures, and more. Schedule a free consultation online to learn more about our services and pricing.